P2118: Throttle Actuator Control Motor Current Range/Performance

Is your scanner showing P2118?

No worries. We'll show you what it means and how to deal with it.

P2118: Throttle Actuator Control Motor Current Range/Performance

OVERVIEWWhat Does The P2118 Code Mean?

The P2118 OBD-II trouble code is one of number of possible codes that indicates that the Powertrain Control Module (PCM) has detected a malfunction with the operation of the Throttle Actuator Control System.

There are six codes that are associated with Throttle Actuator Control System malfunctions and they are P2107, P2108, P2111, P2112, P2118 and P2119. Code P2118 is set by the PCM when the Throttle Actuator Control Motor is out of range or not performing properly.

The PCM controls the Throttle Actuator Control System by monitoring one or more throttle position sensors. The operation of the throttle body is determined by the position of the throttle plate that is controlled by one or more Throttle Actuator Control Motors. The PCM also monitors the accelerator pedal position sensor to determine how fast the driver wants to go and then determines the appropriate throttle response.

The PCM accomplishes this by a changing current flow to the Throttle Actuator Control Motor that moves the throttle plate to the desired position. Some malfunctions will cause the PCM to restrict the operation of the Throttle Actuator Control System. This is known as fail-safe or limp mode where the engine is held at idle or may not start at all.

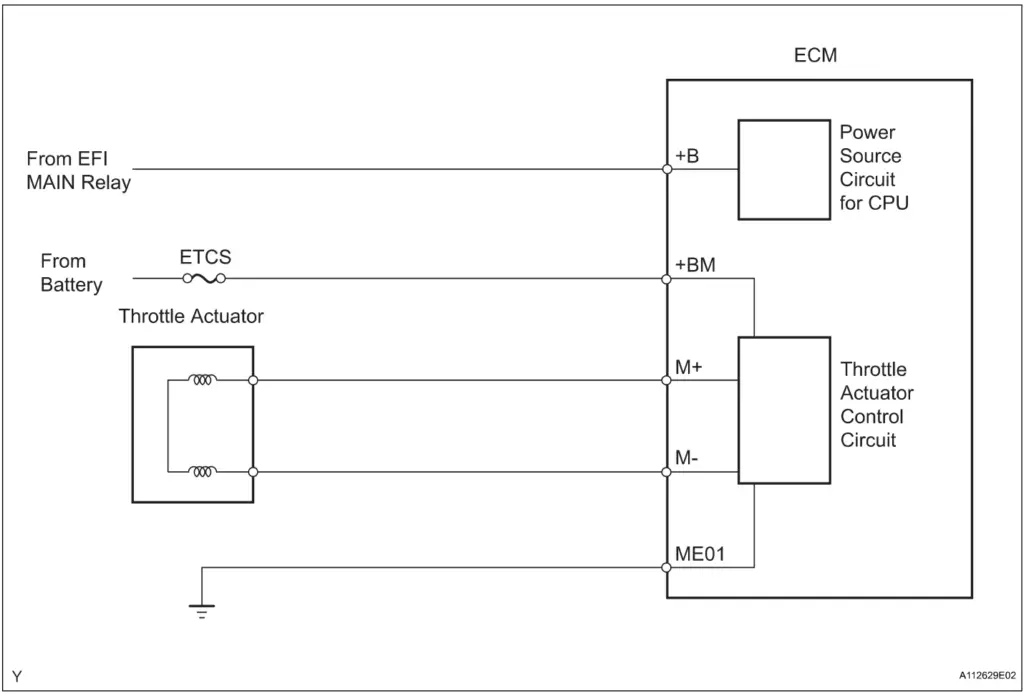

P2118 wiring diagram

What Are The Symptoms Of The P2118 Code?

Symptoms of a P2118 trouble code may include:

- Engine will not start

- Poor performance that progresses

- Little, or no throttle response

- Check Engine Light illuminated

- Smoke from tailpipe

- Increased fuel consumption

What Are The Potential Causes Of The P2118 Code?

Possible causes of this code may include:

- Faulty throttle body

- Dirty throttle plate or linkage

- Faulty throttle position sensor

- Defective accelerator pedal position sensor

- Throttle actuator control motor is defective

- Corroded or damaged connector

- Faulty or damaged wiring

- Faulty PCM

How Serious Is This P2118 Code?

The severity of this code can be moderate to severe based on the specific malfunction.

How Can You Fix The P2118 Code?

Check for TSBs

The first step in the troubleshooting process for any malfunction is to research the Technical Service Bulletins (TSB’s) for the specific vehicle by year, model and power plant. In some circumstances this can save a lot of time in the long run by pointing you in the right direction.

The second step is to locate all of the components associated with the Throttle Actuator Control System. This will include the throttle body, throttle position sensor, throttle actuator control motor, the PCM and the accelerator position sensor on a simplex system. Once these components are located a thorough visual inspection should be performed to check all of the associated wiring for obvious defects such as scraping, rubbing, bare wires, burn spots or melted plastic. Next is to check the connectors to every component for security, corrosion and damaged pins.

The last visual and physical inspection is the throttle plate. With the ignition switch off, you should be able to rotate the throttle plate by pushing in on it. It should rotate to the wide open position. If there is sludge behind the plate it should be cleaned while it is accessible.

Advanced Steps

The advanced steps become very vehicle specific and require the appropriate advanced equipment to perform accurately. These procedures require a digital multi meter and the specific technical references for the vehicle. Voltage requirements will very based of the specific year, model and engine in the vehicle.

Circuit Checks

With the ignition switch in the off position, disconnect the electrical connector at the throttle body. Locate the 2 pins that go the motor or motors on the throttle body. Using a digital ohmmeter set to ohms, check the resistance of the motor or motors. The motor should read approximately between 2 and 25 ohms depending on the specific vehicle (check manufacturers specs for your vehicle). If the resistance is either too high or too low, the throttle body will need to be replaced. If all tests have passed so far, you will want to check the voltage signals to the motor.

If this process identifies the absence of a power source or ground, continuity testing may be required to check the integrity of the wiring. Continuity tests should always by performed with the power removed from the circuit and the normal readings should be 0 ohms of resistance unless otherwise specified by the technical data. Resistance or no continuity is an indication of faulty wiring that must be repaired or replaced.

Hopefully, the information in this article has been helpful to point you in the right direction to correct the problem with your Throttle Actuator Control System. This article is strictly informational and the specific technical data and service bulletins for your vehicle should always take priority.

Recommended Parts

Below are some recommended auto parts to help you address the trouble code affecting your vehicle and get it running smoothly again:

>>> Throttle Plate

>>> Throttle Body (generic)

>>> 1812089 Throttle Position Sensor

>>> Throttle Actuator Control

>>> Pedal Position Sensor

>>> ECU

>>> Twippo 372Pcs Waterproof Wire Connectors Kit

>>> KAIWEETS Digital Multimeter

Note: During the purchasing process, please check carefully whether the part you want to buy fits your car!

Check This Video For Reference

Reference Sources

Diagnostic Trouble Code (DTC) Charts and Descriptions for P2118 – Page 137.