P051B: Crankcase Pressure Sensor Circuit Range/Performance

Is your scanner showing P051B?

No worries. We'll show you what it means and how to deal with it.

P051B: Crankcase Pressure Sensor Circuit Range/Performance

OVERVIEWWhat Does The P051B Code Mean?

Among the countless sensors the ECM (Engine Control Module) has to monitor and adjust in order to keep your engine in running order, the crankcase pressure sensor is responsible for providing the ECM with crankcase pressure values in order to maintain a healthy atmosphere in there.

As you can imagine, there are an abundance of fumes within the engine internally, especially while its running so it is very important for the ECM to have an accurate crankcase pressure value.

It needs this to not only ensure the pressure does not get too high and possibly cause damage to seals and gaskets, but also it requires this value in order to recycle these burnable fumes back into the engine via the PCV (Positive Crankcase Ventilation) system.

Any unused burnable crankcase fumes get routed into the intake for the engine to burn. In turn, collectively improving emissions and your fuel economy. That said, it definitely has a valuable purpose to the engine and ECM so make sure to address any issues accordingly here, as mentioned, with this fault, you may be susceptible to gasket failure, o-ring leaks, shaft seal leaks, etc. As the sensor’s name implies, most times, it is mounted on the crankcase.

Code P051B Crankcase Pressure Sensor Circuit Range/Performance and related codes get activated by the ECM (Engine Control Module) when it monitor one or multiple electrical values operate outside the desire range within the crankcase pressure sensor circuit.

When your instrument cluster is illuminated with P051B Crankcase Pressure Sensor Circuit Range/Performance code, the ECM (Engine Control Module) has monitored an out of range condition or general performance fault within the crankcase pressure sensor circuit.

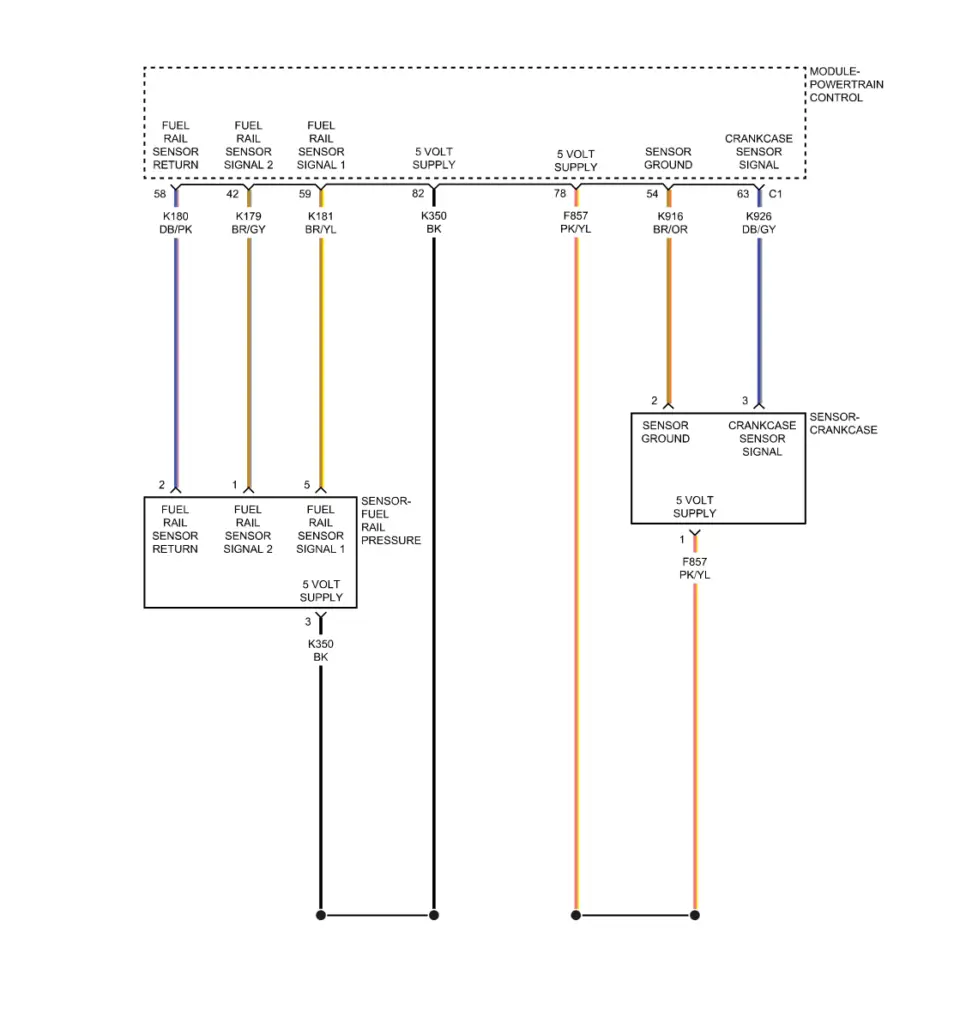

P051B wiring diagram

What Are The Symptoms Of The P051B Code?

Symptoms of a P051B diagnostic code may include:

- Reduced fuel economy

- Leaking gaskets

- Fuel smells

- CEL (Check Engine Light) illuminated

- Engine performing abnormally

- Sludge in oil

- Engine smoking black soot

- High/Low internal crankcase pressures

What Are The Potential Causes Of The P051B Code?

Causes for this P051B engine code may include:

- Crankcase pressure sensor defective

- Internal electrical issue within the sensor

- ECM issue

- PCV (Positive Crankcase Ventilation) valve defective

- PCV issue (broken runners/tubes, disconnected, chafed lines, etc.)

- Clogged PCV system

- Sludgy oil (moisture present)

- Water intrusion

- Engine over-filled with oil

How Serious Is This P051B Code?

I would say, in the grand scheme of things, this fault would be considered moderate-low. Basically, if it fails, you don’t run the risk of immediate drastic further damage.

I say this to stress the point that, it needs to be addressed sooner rather than later. Earlier, I mentioned some of the possible issues if left neglected so keep these in mind.

How Can You Fix The P051B Code?

The first step in the troubleshooting process for any malfunction is to research the Technical Service Bulletins (TSB) for known issues with the specific vehicle.

For example, we are aware of a known issue with some Ford EcoBoost vehicles, and some Dodge/Ram vehicles that have TSBs out that apply to this DTC and/or related codes.

Advanced diagnostic steps become very vehicle specific and may require the appropriate advanced equipment and knowledge to perform accurately. We include basic steps below but refer to a vehicle year/make/model/powertrain specific repair guide for specific steps for your vehicle.

Basic Step #1

First thing, for this fault, I would open the oil cap on the top of the engine (this varies), to inspect for any obvious signs of sludge build-up. Sludge can be caused by something as simple as a lack of oil changes, or following longer than recommended intervals. Speaking personally here, for conventional oil, i run it no longer than 5,000 kms.

For synthetic, I go around 8,000 kms, sometimes 10,000 kms. This varies between manufacturers, that said, from experience, I’ve seen manufacturers set longer than generally recommended intervals for numerous different reasons.

That being said, I stay on the safe side and encourage you to as well. A PCV (Positive Crankcase Ventilation) issue can cause moisture to enter the system causing sludge too. Either way, ensure your oil is clean and full.

NOTE: Make sure to avoid overfilling the engine with oil. Do not start engine if this has happened, drain oil to bring level to an acceptable range.

Basic Step #2

Test the sensor by following manufacturer specific desired values from your service manual. This usually entails using your multimeter and testing different values between pins. Record and compare findings to your make and model’s specifications. Anything outside of specs, crankcase pressure sensor should be replaced.

Basic Step #3

Given the fact that crankcase pressure sensors are typically mounted directly to the engine block (AKA Crankcase), the harnesses and wires involved, are routed through crevices and around extreme temperature areas (i.e. exhaust manifold).

Be aware of this when visually inspecting the sensor and circuits. The fact that these wires and harnesses are subject to the elements, inspect for any hardened/cracked wires or moisture in the harness.

NOTE: The connector should be connected firmly and dry of any oil residue.

Recommended Parts

Below are some recommended auto parts to help you address the trouble code affecting your vehicle and get it running smoothly again:

>>> Engine Oil

>>> Crankcase Pressure Sensor

>>> PCV Valve

>>> ECU

Note: During the purchasing process, please check carefully whether the part you want to buy fits your car!

Check This Video For Reference

Reference Sources

P051B Crankcase Pressure Sensor Circuit Range/Performance, OBD-Codes.