P013A: O2 Sensor Slow Response - Rich to Lean (Bank 1 Sensor 2)

Is your scanner showing P013A?

No worries. We'll show you what it means and how to deal with it.

P013A: O2 Sensor Slow Response - Rich to Lean (Bank 1 Sensor 2)

OVERVIEWWhat Does The P013A Code Mean?

When an OBD-II equipped vehicle has a stored P013A code, it means that the powertrain control module (PCM) has detected a slow response time from the downstream (or post catalytic converter) oxygen (O2) sensor or circuit for engine bank one. Bank 1 specifies the bank of the engine which contains the number one cylinder.

Automotive O2 / oxygen sensors are constructed using a zirconium dioxide sensing element which is protected by a specially designed, vented, steel housing. Platinum electrodes are used to attach the sensing element to wire leads in the O2 sensor wiring harness which is connected to the PCM through the controller area network (CAN).

The PCM is supplied with an electrical signal according to the percentage of oxygen particles in the engine exhaust compared to the oxygen content of ambient air.

Exhaust gases are pushed into the exhaust manifold(s) and down pipe(s) where they flow over/through the upstream O2 sensor. Exhaust flows through the O2 sensor vent holes (in the steel housing) and across the sensing element and ambient air is drawn through the wire lead cavities where it is trapped in a small chamber in the center of the sensor. The trapped ambient air (in the chamber) is heated by the exhaust, forcing the oxygen ions to produce (energy) voltage.

Deviations between the concentration of oxygen molecules in ambient air (drawn into the center cavity of the O2 sensor) and the concentration of oxygen ions in the spent exhaust gases, cause the heated oxygen ions inside the O2 sensor to jump between platinum layers very rapidly and repetitiously.

Fluctuations in voltage occur as the rushing oxygen ions jump between the layers of the platinum electrodes. These variations in voltage are identified by the PCM as changes in exhaust oxygen concentration which indicate that the engine is either running lean (too little fuel) or rich (too much fuel). When more oxygen is present in the exhaust (lean condition), the voltage signal from the O2 sensor is low and is higher when less oxygen is present in the exhaust (rich condition).

This data is used by the PCM primarily to calculate fuel delivery and ignition timing strategy but also to monitor catalytic converter efficiency.

If the O2 sensor in question fails to cycle as rapidly and/or regularly as expected, over a set period of time and under certain predetermined circumstances, a P013A code will be stored and a malfunction indicator lamp may be illuminated.

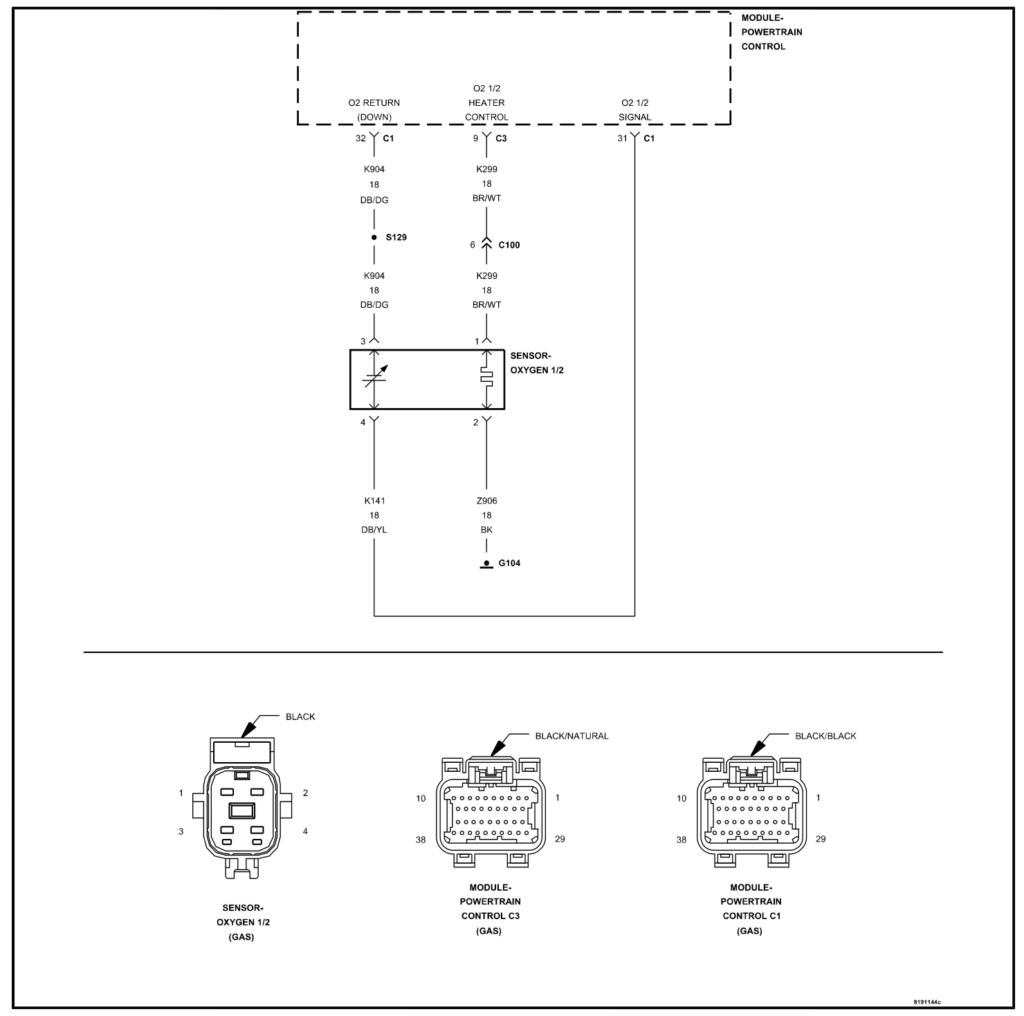

P013A wiring diagram

Other O2 sensor slow response trouble codes include:

- P013B O2 Sensor Slow Response – Lean to Rich (Bank 1 Sensor 2)

- P013C O2 Sensor Slow Response – Rich to Lean (Bank 2 Sensor 2)

- P013D O2 Sensor Slow Response – Lean to Rich (Bank 2 Sensor 2)

- P014C O2 Sensor Slow Response – Rich to Lean (Bank 1 Sensor 1)

- P014D O2 Sensor Slow Response – Lean to Rich (Bank 1 Sensor 1)

- P014E O2 Sensor Slow Response – Rich to Lean (Bank 2 Sensor 1)

- P014F O2 Sensor Slow Response – Lean to Rich (Bank 2 Sensor 1)

What Are The Symptoms Of The P013A Code?

Symptoms of this code may include:

- Lowered fuel efficiency

- A general lack engine performance

- Other related diagnostic trouble codes may also be stored

- Service engine soon lamp illumination

What Are The Potential Causes Of The P013A Code?

Potential causes for this code to set are:

- Defective O2 sensor(s)

- Burnt, broken, or disconnected wiring and/or connectors

- Defective catalytic converter

- Engine exhaust leaks

How Serious Is This P013A Code?

Since a P013A code means that an O2 sensor has remained slow for an extended period of time, it should be categorized as severe.

How Can You Fix The P013A Code?

Some of the main tools that I would require to diagnose a code P013A are a diagnostic scanner, a digital volt/ohmmeter (DVOM), and a reliable vehicle information source (All Data DIY).

Before trying to diagnose a code P013A, all engine misfire codes, throttle position sensor codes, manifold air pressure codes, and mass air flow sensor codes must be diagnosed and repaired. An engine that is not running efficiently will cause all sorts of codes to be stored (and rightly so).

Step 1

Professional technicians typically start with a visual inspection of system wiring harnesses and connectors. We focus on harnesses that are routed near hot exhaust pipes and manifolds, as well as those that are routed near sharp edges like the ones found on exhaust shields.

Search technical service bulletins (TSB) in your vehicle information source. If you find one that matches the symptoms and code/s presented by the vehicle in question, it will very likely aid you in your diagnosis. TSB listings are compiled from thousands of successful repairs.

Step 2

Next, I like to connect the scanner to the vehicle diagnostic port and retrieve all stored trouble codes and freeze frame data. This information may be helpful if the P013A proves to be intermittent so write it down for later. Now, clear the codes and see if the P013A is reset.

If the code is reset, start the engine, allow it to reach normal operating temperature, and then let it idle (with the transmission in neutral or park). Use the scanner data stream to observe O2 sensor input data.

Narrow the data stream display to include only pertinent data and you will see a faster and more accurate data response. If the engine is running efficiently, upstream O2 sensor data should fluctuate regularly between 1-millivolt (.100-volts) and 9-millivolts (.900-olts). If voltage fluctuations are slower than expected, a P013A will be stored.

Step 3

You can connect the DVOM test leads to the sensor ground and signal wires in order to monitor live data from the O2 sensor. You may also use it to check resistance of the O2 sensor in question, as well as voltage and ground signals. To prevent control module damage, disconnect related controllers prior to testing system circuit resistance with the DVOM.

Additional diagnostic notes:

- Once the PCM has entered closed loop operation, downstream O2 sensors should not cycle as regularly as upstream sensors

- Low grade replacement (or remanufactured) catalytic converters are susceptible to repeated failure and should be avoided

Recommended Parts

Below are some recommended auto parts to help you address the trouble code affecting your vehicle and get it running smoothly again:

Note: During the purchasing process, please check carefully whether the part you want to buy fits your car!